There are now technologies that streamline the processes that businesses undertake to develop products for the market.

Whether you have a start-up company or have been around for many years already, you have to take advantage of these technologies, learn about them, and use them to boost your business.

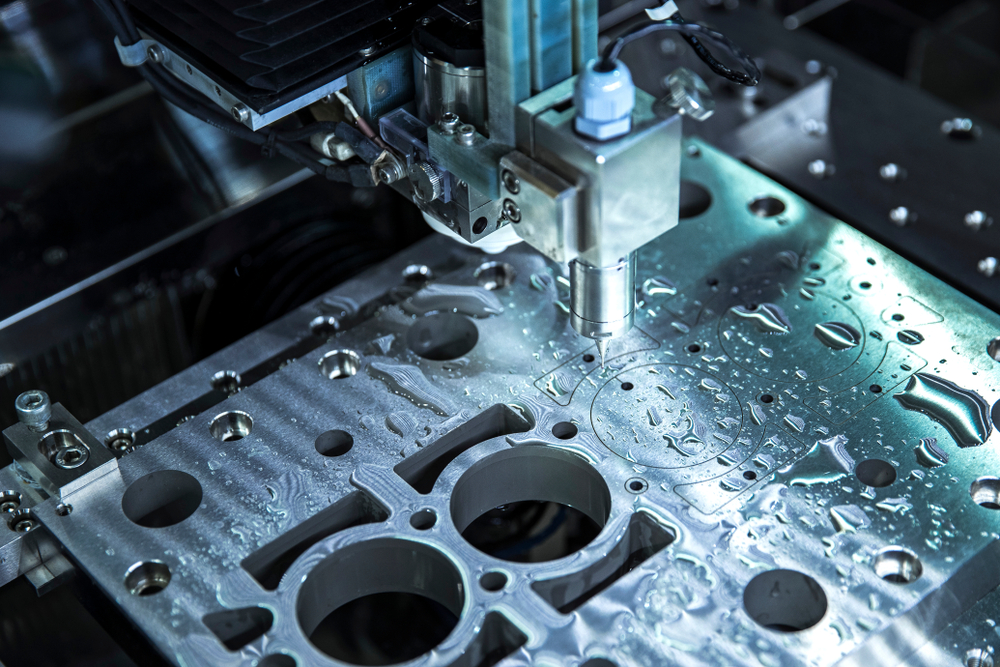

One of the technologies that you should take a look at is CNC machines or Computer Numerical Control Machines. It’s a piece of high precision equipment that accepts computer-generated codes. It then converts the codes into electrical signals through computer software to make accurate, repeated movements.

As a business owner, you can either build CNC machines for in-house use or get help from experts by working with companies that offer CNC machining services.

Depending on your needs, you can reach out to a service provider that specializes in plastic CNC machining or one that focuses on metals. Some companies can even do both.

You can check out this website for more information about plastic CNC machining. These service providers can do rapid manufacturing, rapid prototyping, automotive production, and injection molding, among others.

Read on below to learn more about CNC machining and the advantages that CNC machining services bring to your business.

What’s The Purpose of A CNC Machine?

You can expect a lot of things from a CNC machine. It can use different kinds of materials to carry out different processes like cutting, contouring, engraving, drilling, threading, and milling, among others, more efficiently.

No doubt, CNC machining is a transformative technology and can do wonders for businesses, especially those that belong to the manufacturing sector.

You can expect a more efficient performance and better output from it because it’s digitized and gets powered by computer software.

What Are The Different Types Of CNC Machines?

The good thing about CNC machining technology is that you can have several options when it comes to the type of machine to use depending on your needs.

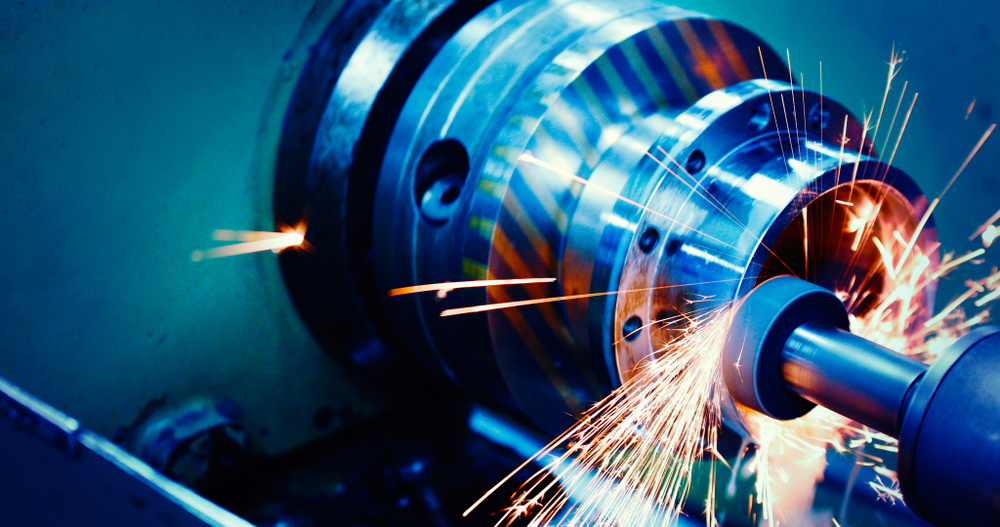

You can use turn-mill centers for turning and milling, lathe machines for cylindrical parts production, grinding machines for grinding and polishing metal components.

If you want one that can move in different directions simultaneously, you can opt for a piece of five-axis equipment.

The technology also allows machine customization to accommodate the needs of your business better. Best examples of custom-built machines are CNC plasma cutters for cutting 2D profile sheets and CNC routers, which you can use to cut intricate shapes of plastic, wood, and other materials.

For cutting purposes, if you want less destructive ones, you can opt to use CNC laser cutters instead of the plasma ones. CNC machines, no doubt, are a revolutionary business technology, having functionalities that work for almost every business owner.

What Are Materials That CNC Machines Can Use?

It’s essential to note that the designing process of a product gets heavily influenced by the materials used for CNC machining.

Thus, with the various options available, you have to choose ones with the right temperature, hardness, chemical resistance, and strength. Again, you can have a lot of choices, but most work boils down to the use of either plastics or metals.

If what you’re after are versatility and durability, metal parts would be an excellent choice. They are the most popular in terms of resistance and strength. CNC machining can use metals for prototyping. These materials can also work in crafting batch production.

Most people prefer metals, especially aluminum, due to it being lightweight and durable. Aluminum is even better in terms of electrical and thermal conductivity.

Even though metals are the more popular choice, it doesn’t mean that plastics aren’t optimal in CNC machining too. They are, and they can work in various production types.

The good thing about plastics is that they’ll require lower costs, add to it the fact that they’re lightweight, and have high resistance and electrical insulation. Nylon, ABS, and poly-carbonate are the most common types of plastics that CNC machining services use.

What Can Industries Benefit From CNC Machining Services?

The truth is different kinds of businesses can benefit from CNC machining technology. Almost all industries operate using machine parts, and they need these parts to work consistently.

To be more specific, some of the industries that can benefit from CNC machining services include the following:

1# Aerospace

For air travel to become reliable and safe, the parts of planes need to work with high precision.

CNC machining services fit the aerospace industry perfectly since they need materials like Inconel, which are hard-to-cut, and only the five-axis machines can manage.

2# Dental

The tools that dentists use should be in perfect shape. The technology helps dental professionals to keep an excellent grip on their devices by providing the best handle texture.

It’s also true for different dental products like implants. The point and angle of these items should be in the right measurements, and it’s what CNC machining can do for the industry.

3# Food And Beverage

Even in the processes that restaurants take to serve customers, CNC machining gets involved. An excellent example would be automated machines that release food and beverage in a push of a button.

Almost all establishments that make or serve food would need the convenience that technology provides to improve customer satisfaction.

4# Electronics

Electronic devices are difficult ones. They have different parts that should work together efficiently and consistently.

An excellent example would be computers that have motherboards and graphic cards consisting of millions of tiny pieces, including panels, metal slats, and small wires.

5# Jewelry

Jewelry manufacturers use CNC machining to cut rings and necklaces from their raw materials. Most pieces of jewelry also come with engraved golds, and it becomes possible with the help of the same technology.

As you know, customers can also request to include some personal touch to their items, which manufacturers can accomplish with the help of CNC machining.

6# Manufacturing

CNC machining also gets involved in one or more stages of product manufacturing. Whether it is on the assembly line or the production point, the different parts of the facilities have to run smoothly to ensure quality results.

7# Medical

Precision is crucial in industries where the life of people can get affected. It’s especially true in the medical field.

Medical devices and equipment have components that need to maintain accuracy at all times. The manufacturing of these instruments can improve with the help of CNC machining solutions.

Surgical implants and orthodontic devices have specialized materials, and their processing needs CNC machining to come up with a complete final product. The medical field also keeps records for documentation and use CNC machines to streamline the process.

As already mentioned above, one of the most important contributions of CNC machining is fast prototyping.

It reduces the time needed for iteration so that high volume production becomes possible if the need arises. It’s going to help the medical industries, especially when new products have to get introduced to the field.

8# Transportation

The vehicles and the electronics behind them require CNC machining to function appropriately and accurately.

Transit, rail, over-the-road trucking, and all other ground transport modes need CNC machining to keep on running smoothly.

Does Your Business Need CNC Machining Services?

The answer is yes. Every business needs it, and it’s hard to find a valid reason why it won’t be right for you. It’s especially true if you’re in the manufacturing industry where you create products.

It’s also applicable for service-based businesses that provide help to companies that develop products out of metals, plastics, and other materials.

The significant reasons why you need CNC machining services are productivity and scaling. You need the technology if you’re going to use machines that consist of intricate details. You also need it if you’re going to create products of the same parts over and over again.

If you’re still on the fence of whether working with CNC machining service providers is worth shelling out money for or not, the following information in this post can help you decide.

The Advantages Of CNC Machining Services For Businesses

CNC machining can help businesses in many different ways. Aside from providing extreme accuracy in product development, such technology can also offer the following:

1. Making Business Operations Simple And Versatile

Traditional production methods take time and are too difficult to operate. CNC machines with computer programming can make things easier and faster.

Tools that businesses use to cut, form, and shape different kinds of materials can get controlled accurately through CNC machining by only pressing several keys that input the instruction program into the computer. It makes it possible to automate the operations of tools.

2. It Provides Convenience

No one can deny it, computers work faster than humans. CNC machines can bring convenience by eliminating man ual work.

It allows machines to work at any time of the day since they’re already digitized. No doubt, it will save time for businesses and give them the chance to make the processes they undertake more efficient.

CNC machining empowers the workforce of any company, making the life of employees more convenient and allowing them to enjoy work more. Machines won’t replace humans; it will never happen. What they do is make things easier for humans instead.

3. Cost Of Production Gets Reduced

Cost-effectiveness is one of the things that every business owner should look into when choosing a new method or technology to incorporate in their daily operations.

CNC machining services are a bang for the buck because it allows the functioning of equipment without the need for many personnel while maintaining accuracy. Such technology assures speed, efficiency, and precision even if production costs get reduced.

4. Prototyping Made Faster And More Accurate

Businesses that belong to the manufacturing sector have to ensure that each step taken in the production stage is error-free. For them to achieve accuracy, they have to implement prototyping.

However, prototyping is both expensive and time-consuming; the reasons why many business owners overlook it or don’t give too much attention to it.

Luckily for manufacturing business owners, CNC machining services allow for the development of more comprehensive designs.

Prototyping becomes more accessible and more affordable with the help of CNC machines, giving businesses the chance to get a better idea of how to produce the best products through mock-ups.

5. Accomplish Complex Designs With Ease

Complex textures and designs are possible with CNC machining, things that could be so difficult or even impossible to achieve using traditional methods.

A CNC machine setup combined with advanced digital software and a talented engineer can accomplish even the most sophisticated of product designs.

Improvements will also become more comfortable along the way, giving you all the chance to market products more effectively.

6. It Makes Sustainability Possible

Since there’s minimal waste involved in the use of CNC machines, sustainability in businesses becomes more achievable. Mistakes in the different processes that the company undertakes also get minimized, which prevents the throwing away of materials.

It also helps that CNC machines can function without the need for any additional parts on its body, cutting expenses again and allowing businesses to allocate some of their budgets to other essential aspects of their daily operations.

7. Avoidance Of Errors

As already mentioned above, CNC machining provides accuracy more than any other existing method. And since the operator only has to press a few keys to input commands onto the system, it minimizes human errors, which will cost businesses a lot of money.

Companies only have to make sure that they’re going to hire someone reliable to operate CNC machines correctly. Once the specifications get entered the right way, such technology can automate the rest of the processes.

8. Creating A Work Environment That’s Safer For Everyone

When you use the traditional methods, your employees have to manually handle punches, lathes, drills, and other machines.

It increases the risks of accidents. The good thing about CNC machining is that one can operate it from a distance, guaranteeing safety to workers.

9. Perform Better Than You Competitors

Accuracy and Speed are what CNC machines are known for in the market. Using them would mean getting ahead of your competitors who still settle with the traditional methods.

It allows you to meet demands faster and better keep up with the changing market. All of those things will ultimately result in more satisfied customers coming your way.

Final Thoughts

As a business owner, you can either settle with the traditional methods and hinder the growth of your company or use CNC machining services to catapult your business to success through the benefits mentioned and discussed above. Take action now and make the right decision!